There are different types of welding in the industry.

Knowing the differences is the first step to doing a good job. One of those welding types is tee joint welding.

Tee joint welding is one of the most popular welding joint types. It can be tricky for those who are not yet experienced.

This article provides some important guidelines that will help beginner welders into improving their welding skills.

What is a Tee Joint?

Before going further, let us first talk about tee joints first.

What is a tee joint, and what does it look like?

A tee joint happens when two pieces of metal meet at a 90-degree angle. When they’re welded, they form a joint that resembles a T letter, which is why it is called a T (tee) joint.

Read Also : Easy Lap Joint Welding: Definition, Types and Techniques

Types of Tee Joints

Although they look similar, tee joints have different types.

This is because how two metals meet at one point can lead to various welding situations. And that different situations require different welding techniques.

It also depends on what level of strength is needed.

Here are some popular examples of tee joints:

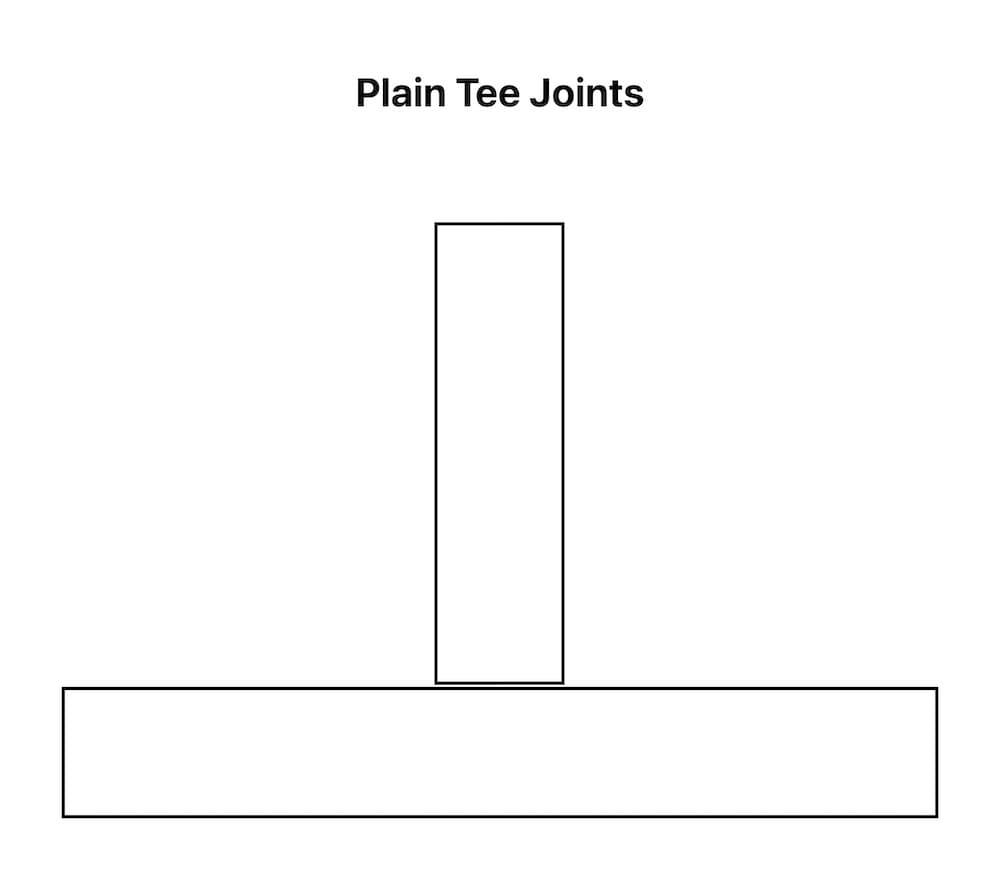

1. Plain Tee Joint

This type of tee joint has the simplest form.

The metal the welder holds has a flat shape at the end, which allows it to be welded immediately into the body of the other metal.

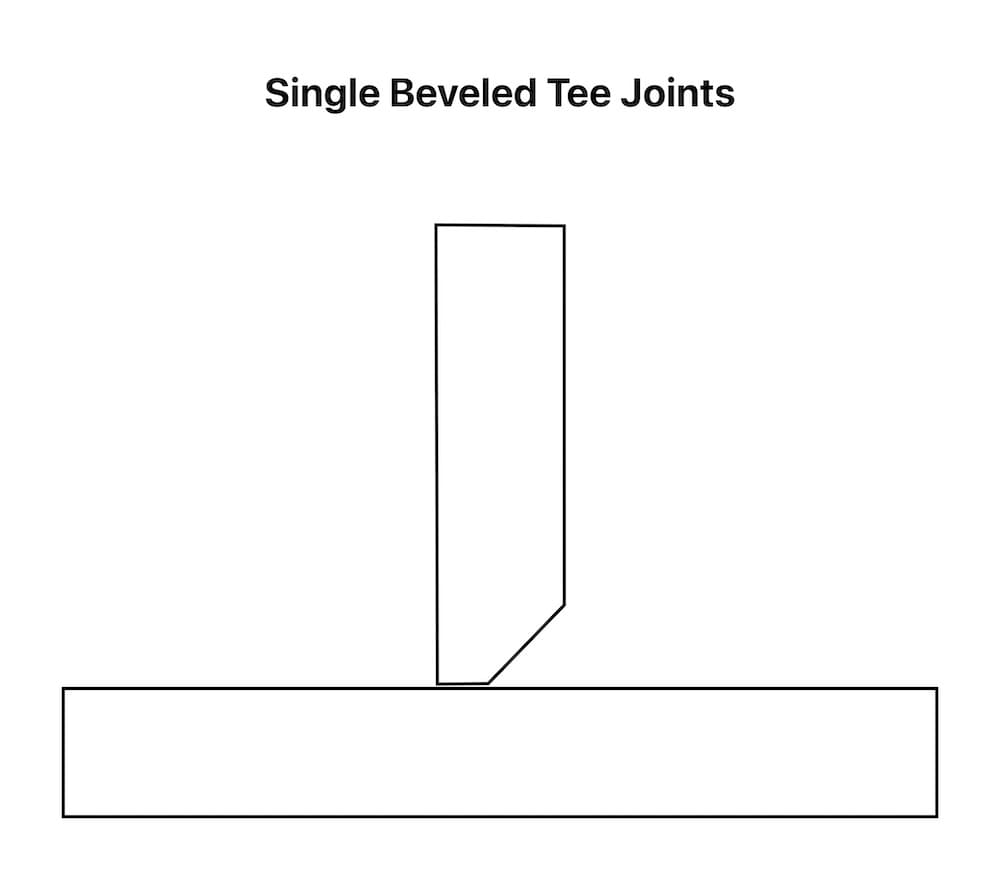

2. Single Beveled Tee Joint

When the tip of a metal piece is cut at a 45-degree angle at one side, it creates a beveled look.

Hence, the joint is called a single beveled tee joint. This joint type is more difficult than the first.

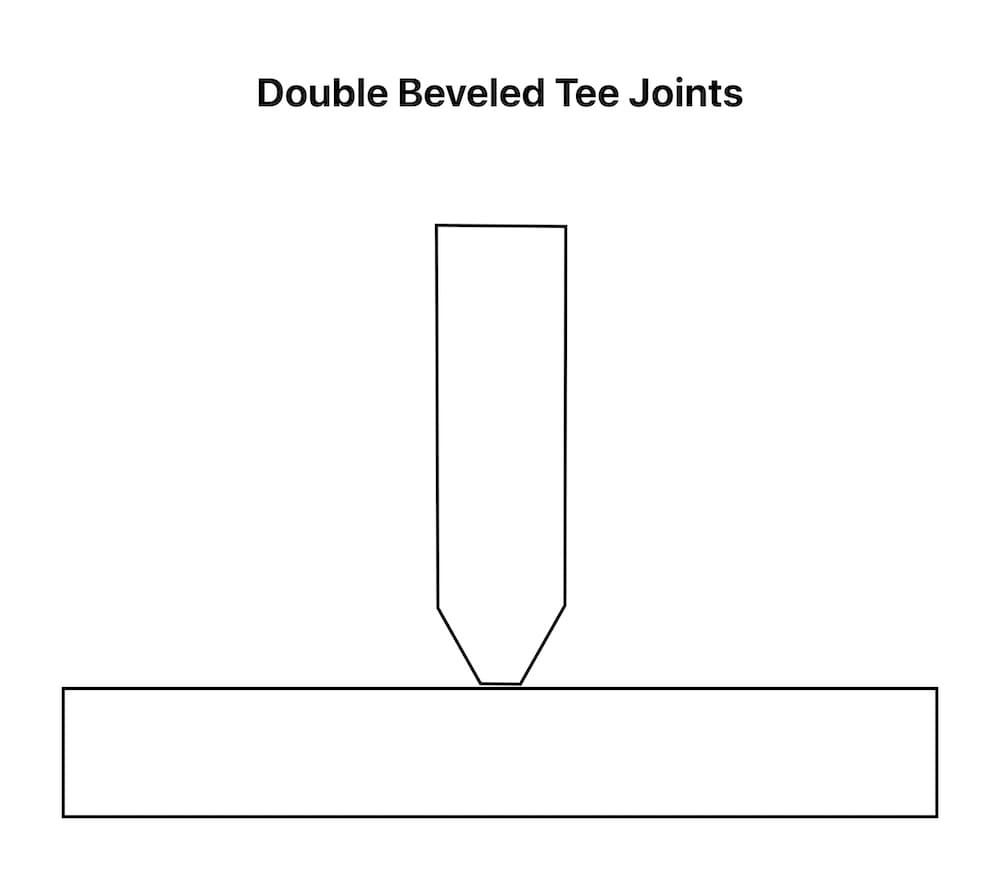

3. Double Beveled Tee Joint

Double beveled tee joints happen when both sides of the metal ends are cut at a 45-degree angle.

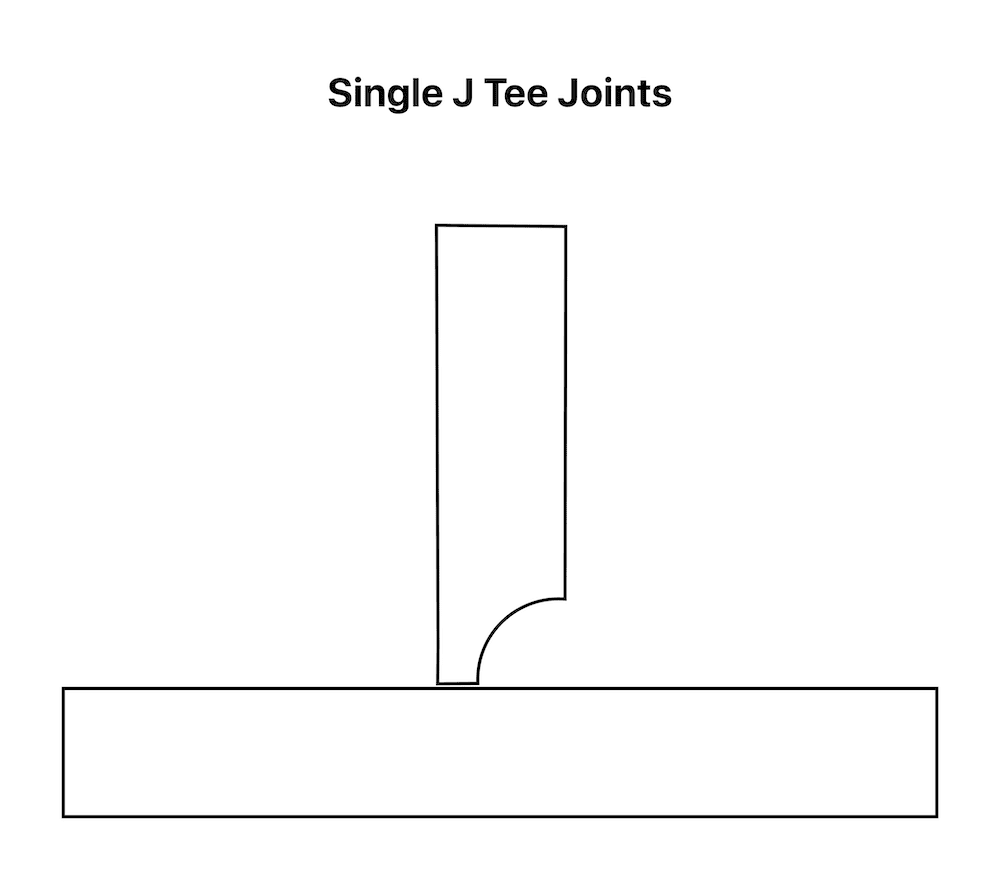

4. Single-J Tee Joint

With Single-J tee joints, welders will face a situation where one of the metals is cut at a 35-degree angle at one side.

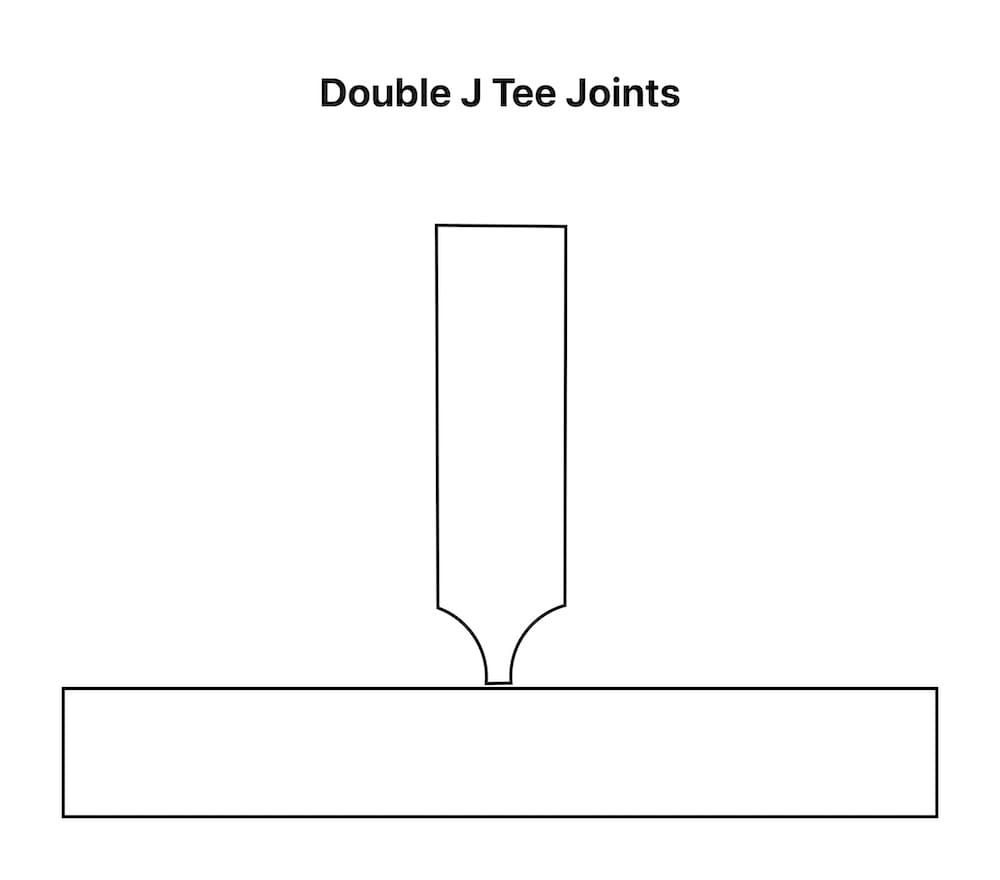

5. Double-J Tee Joint

For this joint type, two sides of a metal end are cut at 35-degree angles.

Tee Joint Welding Strength

Several things may affect the strength of your weld.

They include the quality of welding materials used, the thickness of the materials used, and the welding techniques.

1. Metal Quality

A good weld relies on the quality of the material.

Do not try to compensate for quality to save some cents because a good welding will save you money in the long run.

2. Metal Thickness

The thicker the material, the trickier the welding process will be.

It doesn’t mean you have to pick a thinner metal, though. It only means you’ll have to be more thorough.

But with the right technique, you shouldn’t fear making a mistake.

3. Welding Techniques

A good technique for tee joint welding will help you save time on the welding process and give you high-quality welds.

Good techniques include good application and picking the right welding method.

Tee Joint Welding Preparation

Making a great quality weld requires good preparation.

You’ll need to make sure you follow each step to ensure your welding process goes smoothly.

Below, you’ll find the list of several things you need to check before welding.

1. Choosing The Welding Material

You can use any metal for your tee joint welding project.

Pick one that suits your needs. Some of the best metals you can work on include aluminum, carbon steel, and titanium.

Each of those metals mentioned above has different levels of hardness and thickness.

Remember that thicker metals may require longer welding time, but skipping them is not an excuse. It’s just a part of the process.

2. Choosing The Welding Method

After you decide what kind of metal works best for your project, it’s time to determine the welding method.

To help figure out what method suits your need, check the thickness and the type of materials.

However, you’ll also need to make a sound decision based on your current equipment.

Skills and experience will also play a role in determining the weld quality.

3. Preparing Your Workspace

Before starting a welding project, make sure your workplace is ready.

A clean working station helps you focus on the job, so remove anything that will distract you from completing your project.

Preparing all the tools beforehand will also help you work more efficiently.

You can work faster if you can find all the tools nearby. If possible, keep everything within your reach.

But your workspace is not the only thing you need to keep clean.

Cleaning your material before you start welding may sound like a waste of time. But you can weld better with no dirt in the way.

Read Also : Corner Joint Welding: Definition, Types and Easy Tips

Tips on Welding a Tee Joint

While welding quality depends on the welder’s skills and experience, there are a number of things a beginner welder needs to know.

By learning some tips and tricks, a welder can learn faster and improve their skills in no time.

Here are some tee joint welding tips:

- Use a clamp to keep your metal in place. Keep the clamp on until you’ve done your work, and the metal cools off.

- Check the alignment to make sure it’s straight.

- Adjust your welding setting to suit the type of material. Check the thickness of your metal and set your welding machine appropriately.

- Keep your hands steady while welding. A shaky and inconsistent movement leads to uneven beads.

- Make sure you weld deep enough to the root of the joint. There’ll be a chance of your weld breaking if it’s not properly welded.

- Check your work and re-do it if necessary. This is important to make sure your work meets the standard.

After preparing and checking, you may want to take notes about some things you want to improve.

Review your performance and think about what would make your work faster or better next time.

Mastering tee joint welding is not easy, but it will get easier with a lot of training and increasing work hours.

Preparation is also the key to a successful welding project, as it involves knowledge of materials, tools, and techniques.