When it comes to joining two metal pieces together, you can easily go for lap joint welding.

This method has several applications that can be useful for your next welding project.

This welding technique may look simple, but this simplicity comes with a few issues.

You will learn about them further in the article.

But first, let’s discuss the basic.

What is Lap Joint Welding?

A lap joint happens when a metal piece sits on another and is welded together at the spots where the two meet.

Lap joint welding is thus the welding technique applied to this type of joint.

Unlike tee joints and corner joints where the welding occurs at one or both edges of the metal, lap joints involve a wider area.

This wider area is where the two metals overlap with each other.

Manufacturers use lap joints on metal sheets or materials made of steel or aluminum.

Lap joints can provide strength for the metal so that it becomes resistant to the stress caused by their environment.

Read Also : Detailed Guide to Butt Joint Welding: Types, Pros and Cons

Types of Lap Joints

You can adjust a lap joint to suit your need depending on the required strength.

You can modify the joint by welding at specific spots of the metal. And based on the spot placement, there are three different types of lap joints.

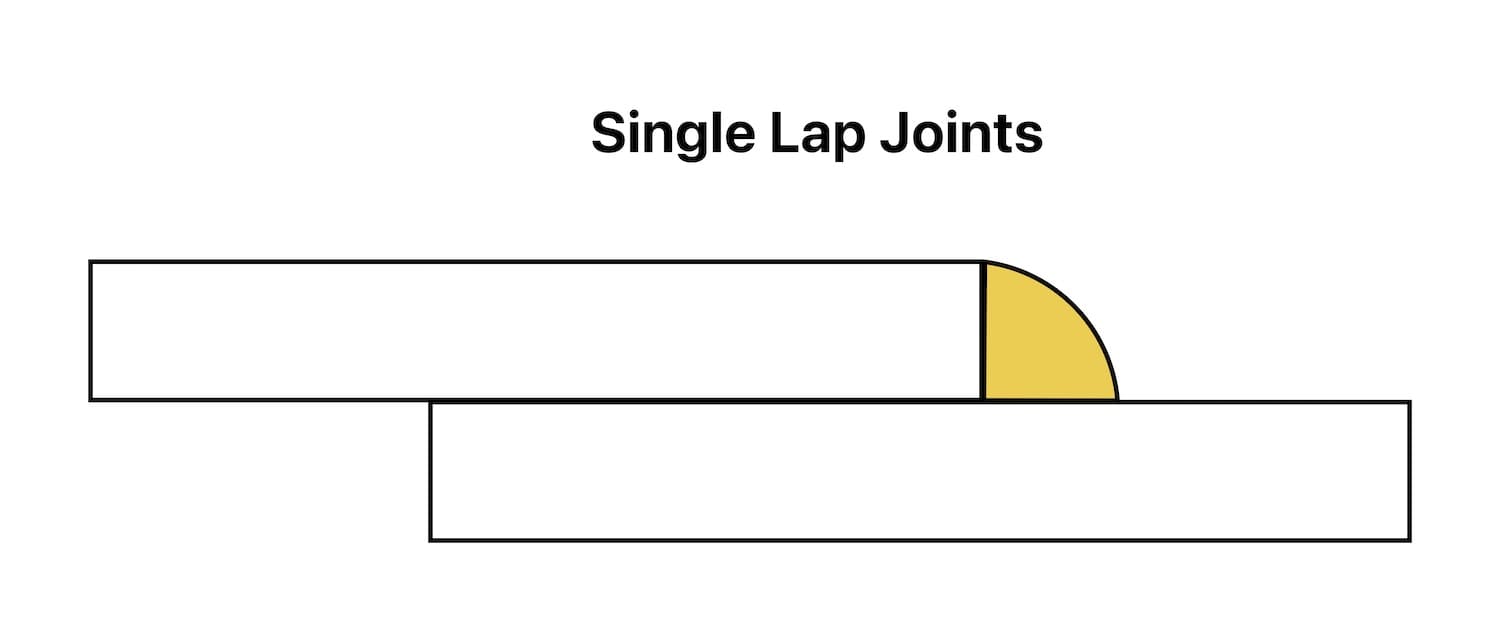

1. Single Lap Joints

When you weld at one side of a lap joint, you call it a single lap joint welding.

It’s fast and efficient, though it may not be as strong as the second type. This type of joint is also called single-fillet lap joint.

But you don’t create single lap joints for their strength.

You’ll need this joint type when you need a temporary framework, for instance. Using this type of joint, you can quickly finish the job and use the extra time to work on something else.

However, the above point means that you shouldn’t use single lap joints to create something that is meant to carry heavy loads.

You can use the next type for this purpose.

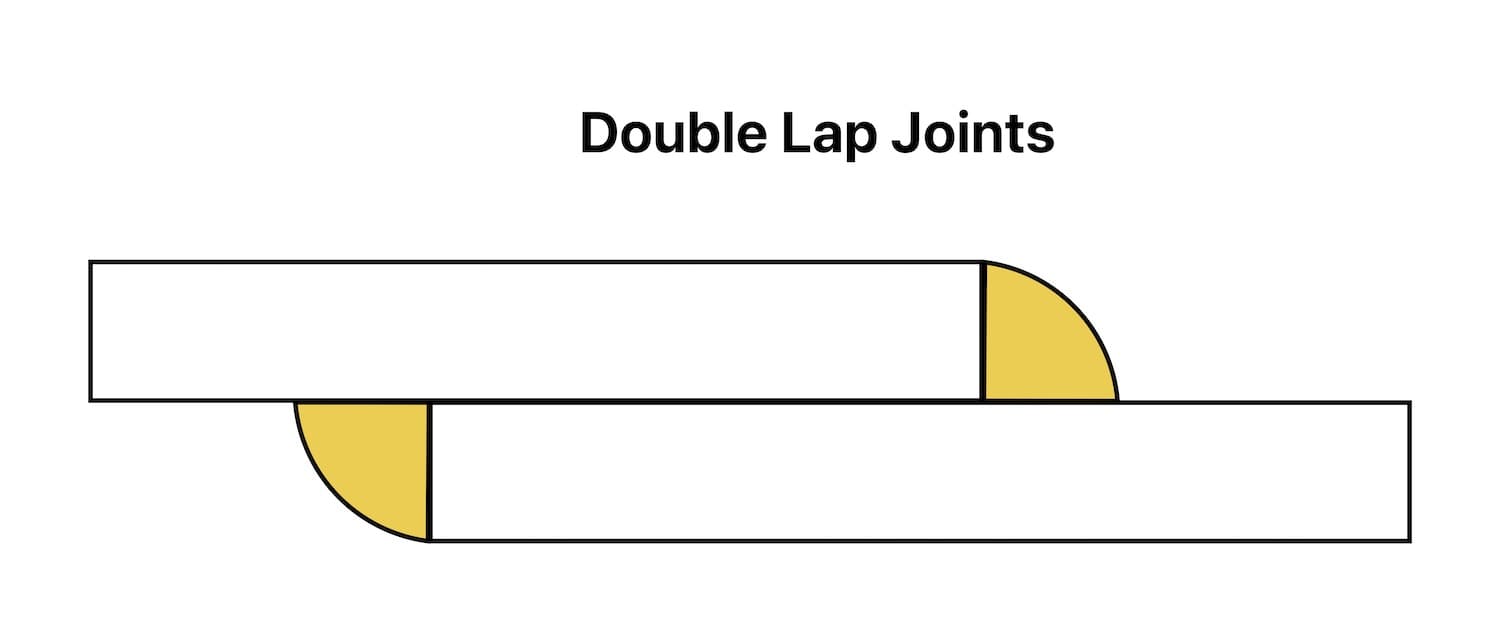

2. Double Lap Joints

Also called double-fillet lap joint, this type of joint provides more resistance against heavier loads. A double lap joint occurs when you weld at both sides of the joint.

Double lap joints can be really strong if the welding is done properly.

In fact, they can be as strong as their metal base. That’s why, you need do a thorough check after doing your work to ensure the quality of your weld.

Compared to the first type, this lap joint is more rigid, which makes it a perfect solution for permanent applications.

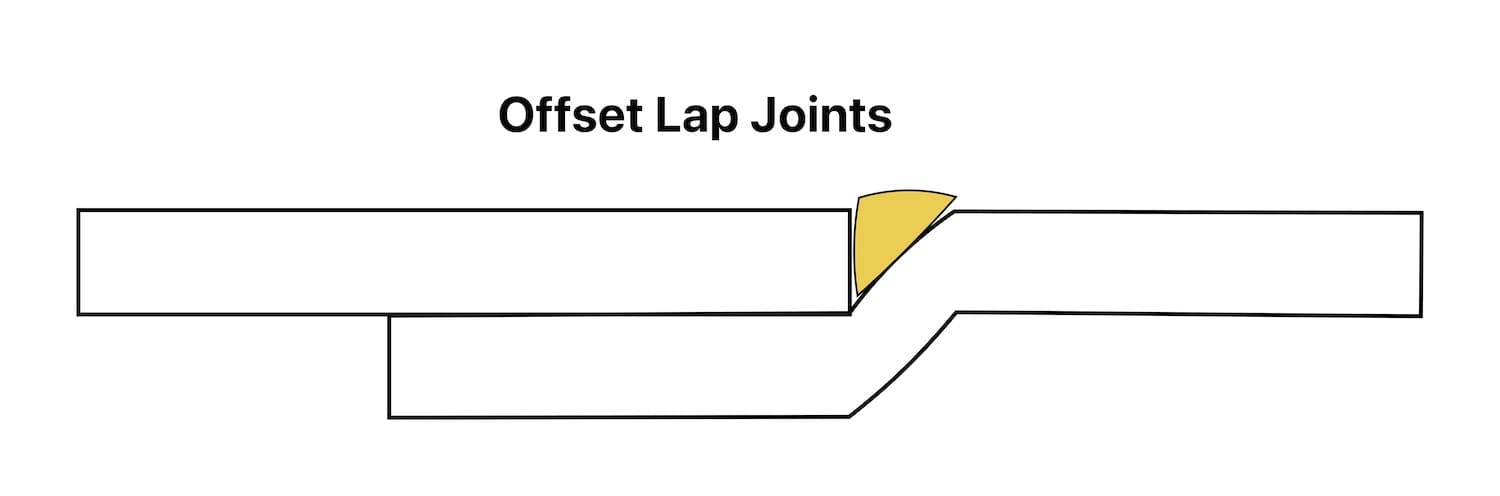

3. Offset Lap Joints

In the first two types, there is the difference in height as one metal is positioned on top of the other.

Offset lap joints, however, allow the joined parts to be on the same level.

Offset lap joints require little modification.

You will need to bend the end of the bottom metal to accommodate the top one. This way, the top metal can fit into the curve you created.

This lap joint type is more difficult than the other two.

However, it provides a stronger weld, so it’s suitable for any application that deals with carrying heavy loads.

Pros and Cons of Lap Joint Welding

Before using this welding method, you must know that lap joint welding has several pros and cons.

Learning them will help you minimize the risk of making mistakes and sharpen your knowledge of this welding type.

Pros

- Lap joint welding doesn’t require specific tools and equipment, so it’s pretty simple and straightforward.

- The joint type doesn’t require placing it on a specific angle, hence the ease of application.

- Although alignment will make a lap joint looks better, it is not paramount for the success of your project. A slight misalignment is forgivable.

- Thanks to its simple design, you can quickly finish the job and save time and effort.

- A lap joint looks smoother than other types, thanks to its even distribution of weld material.

- You can use different types of metal for this welding project. While in some joint types, this is not possible.

- A lap joint is strong, though its strength is not unlimited.

Cons

- Although it can withstand stress at a normal level, a lap joint can break if it bears too many loads.

- It has limited use. You can’t use it for construction-related projects or other projects that require a very strong joint since its ability to bear load is quite limited.

- While the application may not require specific tools, you may need to have one to inspect your work. This is because you can’t see the inside of lap joints.

- Lap joints are prone to rust and corrosion because the design allows some gaps to happen. Gaps can also cause leaks in some applications.

- While it doesn’t take too much time to create one joint, creating many of them will have you spend a lot of time on this welding project. This is because you will have to work on them one by one.

Read Also : Edge Joint Welding: Definition, Simple and Effective Methods

Lap Joint Welding Tips

Before starting to work on lap joints, there are some things you need to prepare.

You can find a list of some useful tips below.

- Clean your workspace, including all your tools and equipment. Remove anything that distracts you. This is so you can work faster and without a hitch.

- Clean your materials. Brush your metal or use sandpaper to smoothen the surface. This is a smooth welding process.

- A small gap between your metal will help the weld go deeper, hence strengthening the bond. So, leave a small gap between your metal if you want to make the joint stronger.

- Ensure your weld covers all the gaps to prevent leaks, eventually resulting in corrosion.

- Although this joint type doesn’t require much alignment, try your best to align your materials nonetheless. This will result in a better look and easy application.

Understanding the pros and cons of lap joint welding can help you prevent from making a mistake.

But, if it happens, remember that you can always learn from your mistake.