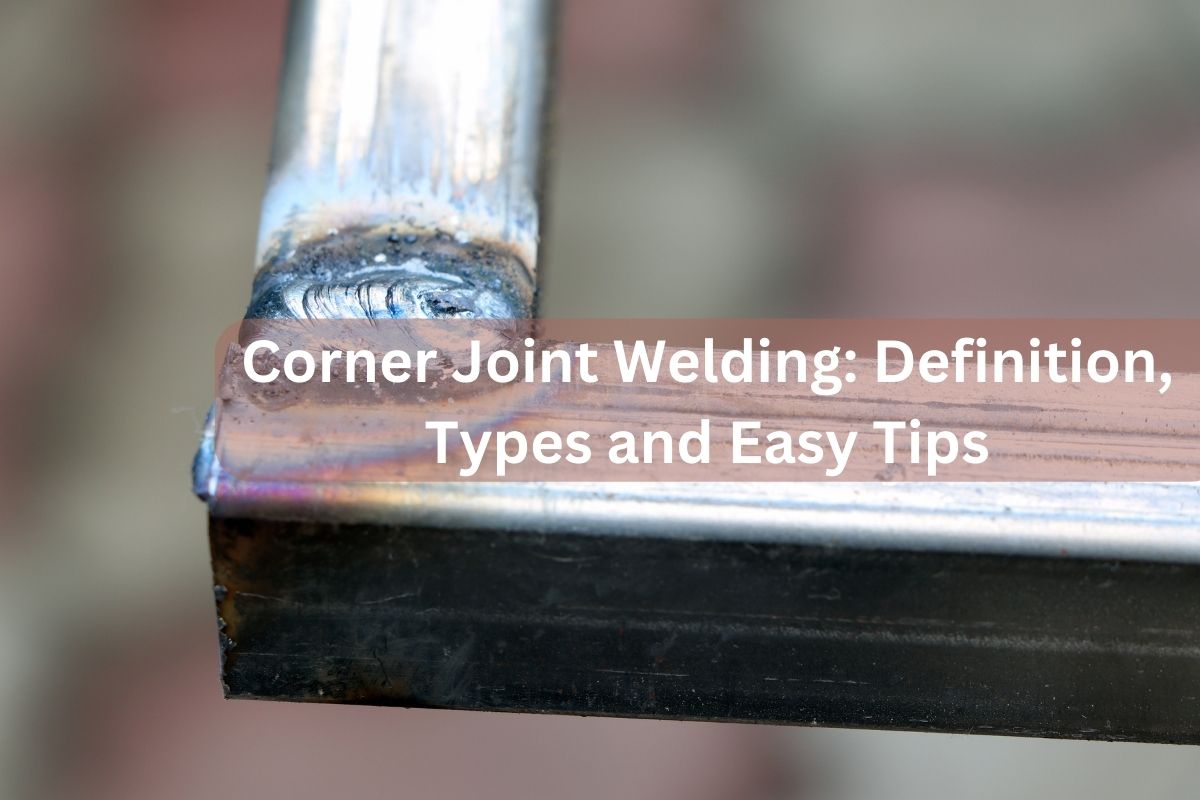

Corner joint welding has many applications across different industries. This is the reason why knowing this welding technique is important.

This technique may be more straightforward than other welding techniques, but it doesn’t mean you can skip learning the basics.

This article will give you all you need to know about corner joint welding.

Definition of Corner Joint Welding

This welding type gets its name from a specific type of joint, i.e., a corner joint.

It is called a “corner joint” because it is made by welding two pieces of metal at a 90-degree angle (right angle), creating a corner.

To make a corner joint, a welder must bond two metal pieces.

But those metals do not form a T shape, unlike a tee joint. They will form an L shape because the ends of metal pieces meet each other.

Various industries, such as construction and manufacturing, have often used this type of welding joint.

This is because good quality corner joints can help the whole construction withstand pressure.

Read Also : Edge Joint Welding: Definition, Simple and Effective Methods

Types of Corner Joints

After learning about corner joint welding definition, you can now learn the types of corner joints.

Generally, there are two types of corner joints, which include closed corner joints and open corner joints.

In reality, these two corner joint types can be divided into three categories:

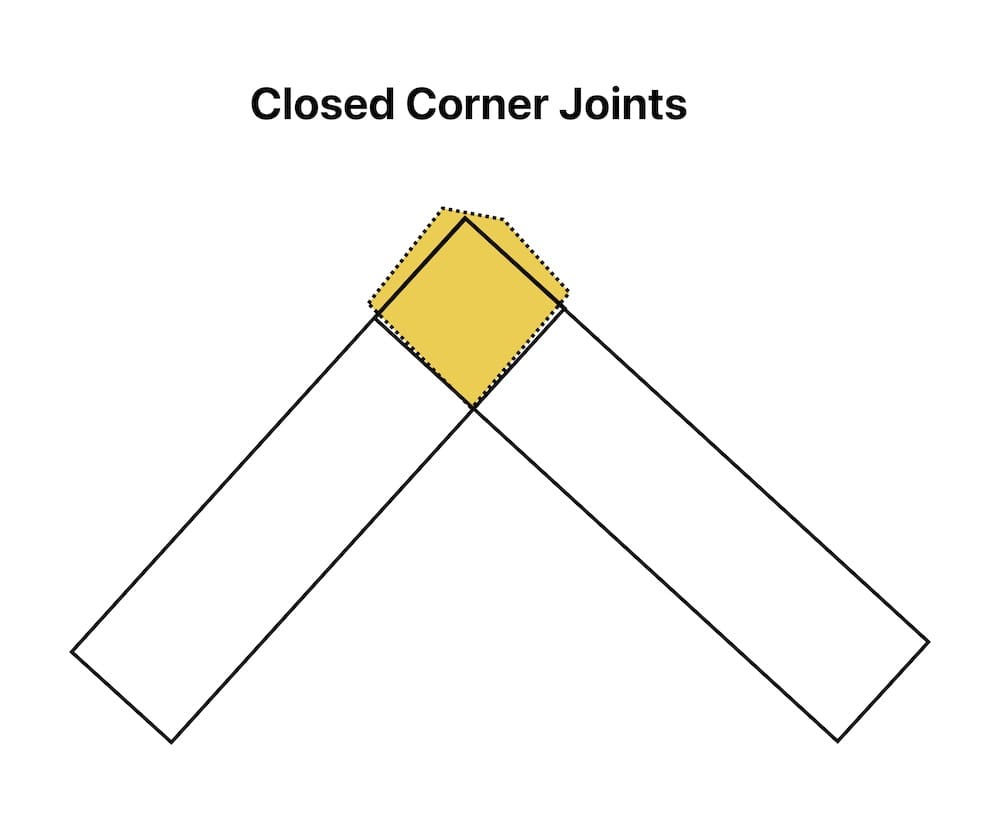

1. Closed Corner Joints

Closed corner joints happen when the end of the metal meets the endpoint of the other. It is called “closed” because one of the metal pieces “closes” the other’s edge.

Generally speaking, you won’t need a filler with this joint type. And when you use it, you only need a little.

This type of joint is best used for thin materials that don’t require much strength, such as sheet metals.

And since the application of this welding technique usually includes thin materials, you will need to use low heat to avoid burning out.

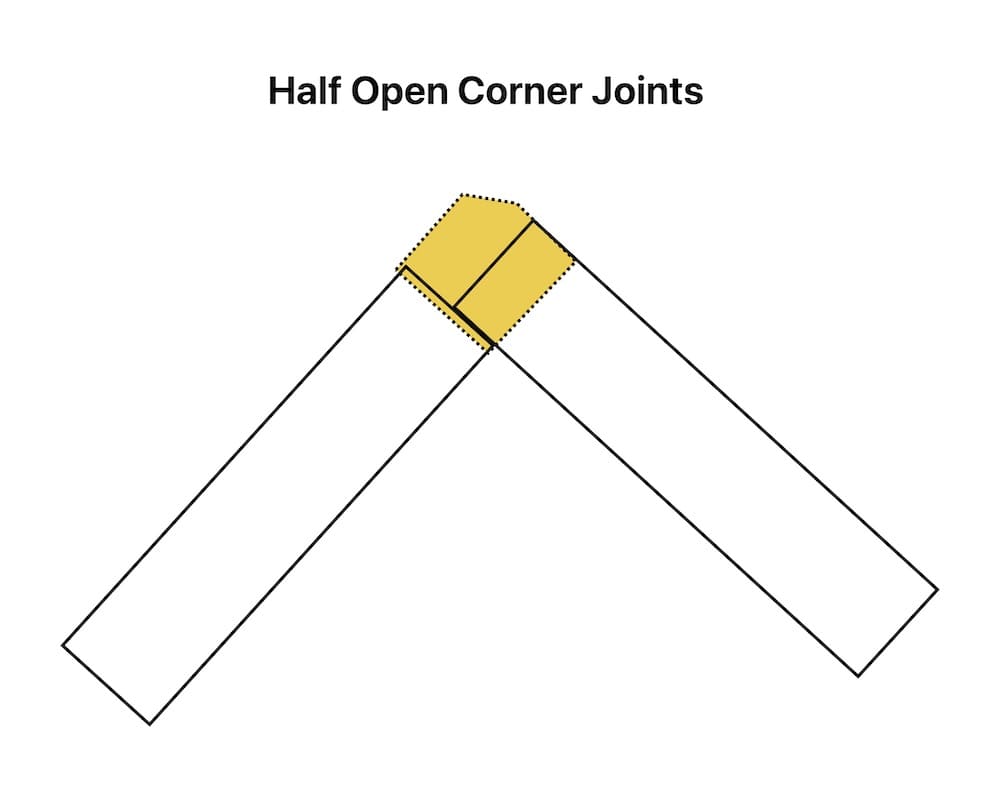

2. Half-Open Corner Joints

In some corner joints, you will find that the edge of one metal piece covers half of the other. This type of corner joint is called a half-open corner joint.

Compared to the first corner joint type, half open corner joints have a higher penetration level.

This type of joint suits a thicker material as well, usually that which has a thickness of 12 gages and more.

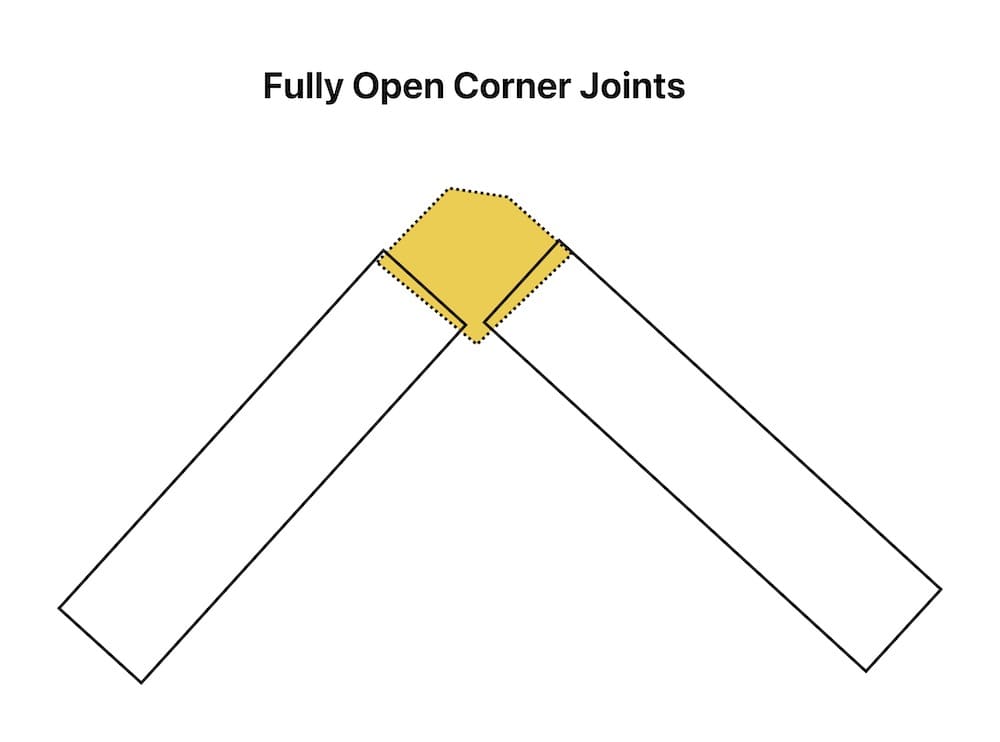

3. Fully Open Corner Joints

The joint is called fully open when you can see both edges of the metal pieces you’re working with.

Since the gap between those edges is bigger, this type of corner joint requires a deeper penetration than the first two.

Given the open edge situation, you will need a filler to close the gap. It won’t be enough only to use fire to melt the metal pieces. Fillers help bond two pieces of metal together.

This type of corner joint works best for metal with a high level of thickness. You will need to weld both sides of the joint to strengthen the bond.

Corner Joint Welding Tips

With different types of corner joints, you may have a problem figuring out which type works best for you.

You might also wonder if there are other things you can do to improve your performance.

If you answer “yes” to both questions, check some of the corner joint welding tips below:

- Choose welding materials according to the strength needed for your project.

- Check and prepare the tools and equipment.

- Determine the type of corner joint you want to go with, then pick a technique that suits your purpose.

- Closed corner joints are best for thin materials, while open corner joints suit thicker materials.

- While working on your project, make some adjustments when necessary.

- You may need to lower the heat level and fasten your welding speed while working with thin materials. This is to avoid burning your work.

- Smoothen the closed corner joint’s transition by grinding the metal piece beforehand.

Pros and Cons of Corner Joint Welding

Like other welding techniques, the corner joint has its own share of advantages and disadvantages.

Here you can find below the pros and cons of this welding technique.

Pros

- When it comes to welding two pieces of thin metal together, you can agree that this welding technique is the easiest way you can go with. It creates a bond that is both strong and reliable.

- It’s easier to work on all sides of the metal at the same time. And as you can control the heat and penetration levels easily this way, your welding will become more accurate.

- Working on all sides of the metal also saves you time and effort. Hence, compared to other methods, corner joint welding is relatively quick.

- Corner joint welding is versatile as it works with thin and thick metal. It also works on different types of materials with different degrees of hardness.

Cons

- Although corner joint welding is an easy and quick method, it can be difficult to get a high quality weld from this technique. The awkward angle makes it difficult to apply the proper level of heat and pressure on the material.

- Despite its reliability badge, corner joint welding often has defects. This is mostly due to the fact that this joint type often faces a lot of stress from its environment.

- The uneven finish is commonplace with this welding technique. You can expect to see bumps on the surface of your material.

- You’ll spend much time working on thicker metal pieces, especially if you’re dealing with fully open corner joints. Yet, if you want a strong weld, you cannot shorten the time.

- It takes time to master this welding technique. You will have to go through specialized training to master this skill. Not only because this technique is difficult but also because it requires the use of different kinds of equipment and tools.

Read Also : Easy Lap Joint Welding: Definition, Types and Techniques

After finding the answer to the question, “What is a corner joint welding?”, you can lead yourself to learn more about this welding technique.

Knowing different types of corner joint welding will help you determine the right pick for your next project.

While understanding the pros and cons can help you avoid making a mistake and prepare to fix one when it happens.