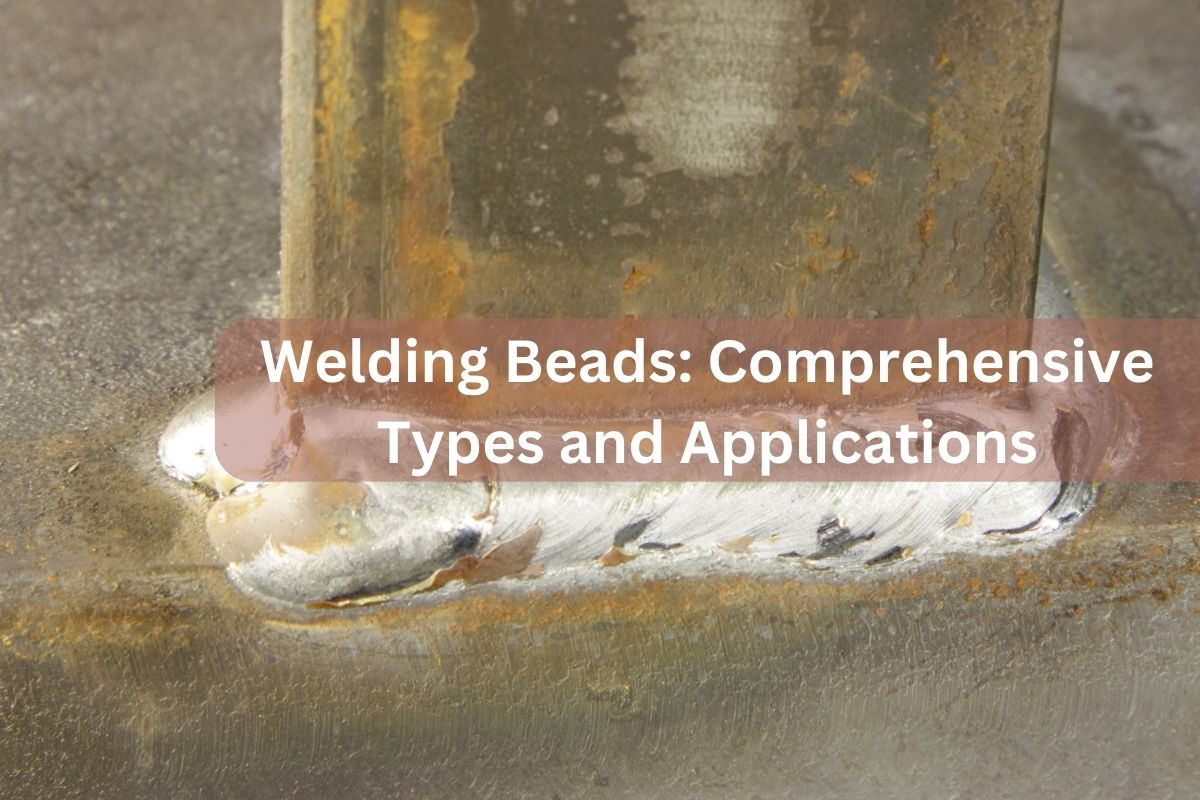

Welding is the process of joining metal using electrodes and metal liquid.

By doing this process, a welder will create a different shape and follow a blueprint of a design. One of the most essential components in it is welding beads.

Welding beads itself are part of most welding processes and methods.

They are the result of the deposition of molten metal onto the surface of the base metal, creating a continuous or intermittent bead.

The weld bead serves to join the two pieces of metal and provides structural integrity.

This article will explore what welding beads are, the different types of welding beads, and their applications.

Definition of Welding Beads

A welding bead results from molten metal deposition onto the surface of the base metal.

During welding, the bead coming from the welding electrode or filler metal base will melt and fuse with the base metal.

Then, it creates a continuous or intermittent line of metal.

The welding bead’s shape, size, and appearance may vary depending on the welding process and the type of joint being welded.

Read Also : Inductance in Welding: Don’t Let It Ruin Your Welds

Types of Welding Beads

There are several types of welding beads based on how it is made.

In addition, the type also depends on how the process takes place.

Below is the list of welding bead types.

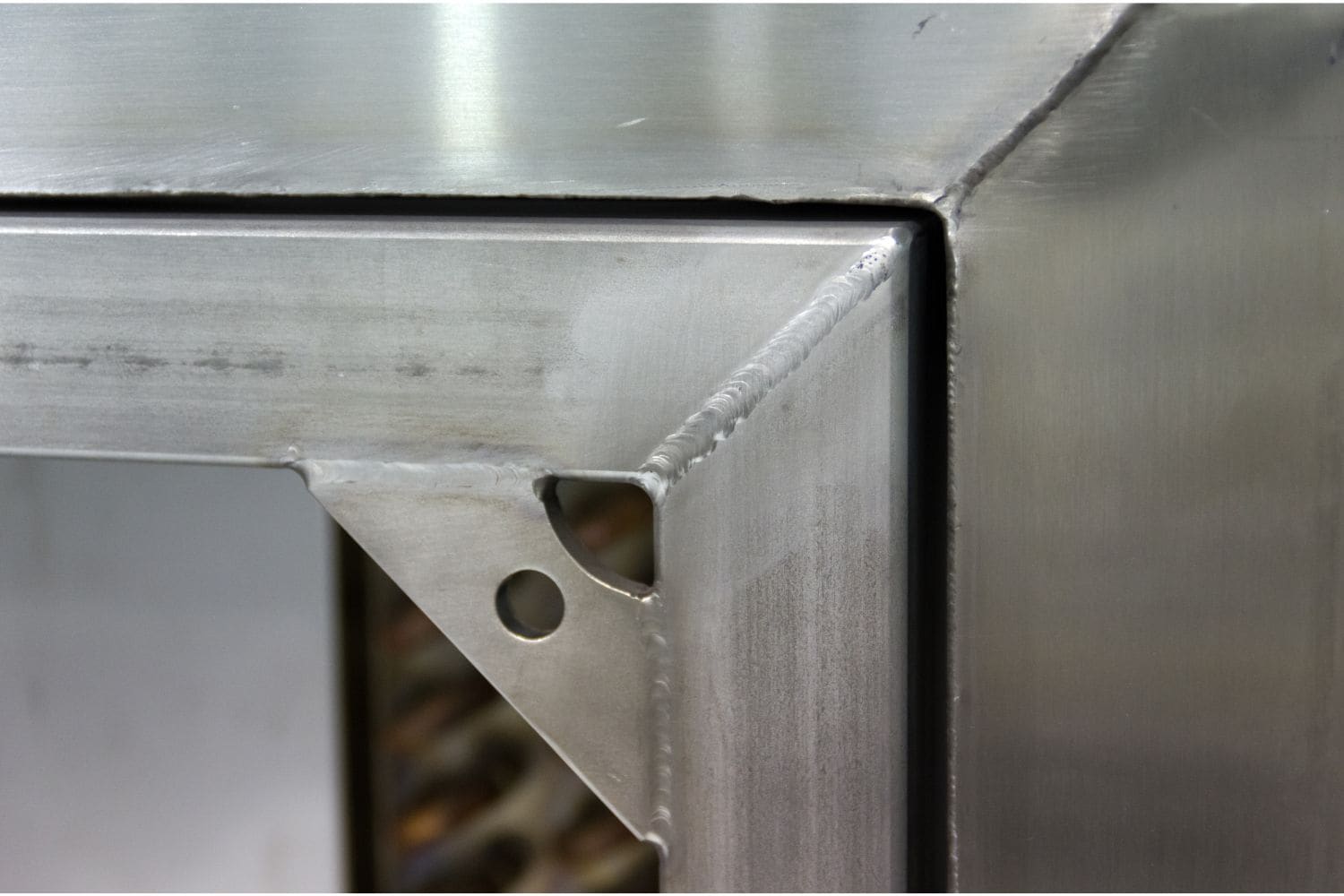

Fillet Weld Bead

A filet weld bead is a triangular-shaped weld bead. It comes as a result of joining two pieces of metal at right angles.

In addition, the bead is more common in construction, manufacturing, and automotive applications.

The fillet weld bead provides superb strength and load-bearing capacity.

It is also more durable than other-looking beads. Thus, it is suitable for heavy-duty applications.

Butt Weld Bead

When a welder joins two metals together by welding both ends of the tip, it creates a weld bead.

A butt weld bead is common in structural complications like control, bridge building, etc.

The butt weld bead can be formed as single or multiple beads, depending on the joint’s size.

Moreover, there can also be other materials to create different shapes of metal beds. A welder may collect some butt weld beads in the process and use it later.

Thus, butt weld beads are more like the leftover result of the welding but famous enough to make it a cooperative material everyone can leave to.

Read Also : Detailed Guide to Butt Joint Welding: Types, Pros and Cons

Plug Weld Bead

A plug weld bead has a circular weld bead shape. It comes from two pieces of metal joined together.

In addition, the weld bead is commonly used in automotive and aerospace applications.

Because of its shape and durability, the plug weld bead provides excellent strength and creates a sturdy build.

It is also useful to join welding metal parts without requiring access to both sides of the joint.

Hence, a welder usually uses plug weld beads to create parts of any automotive products or aerospace ones needing a sturdy material.

They are strong and also last longer than other weld beads.

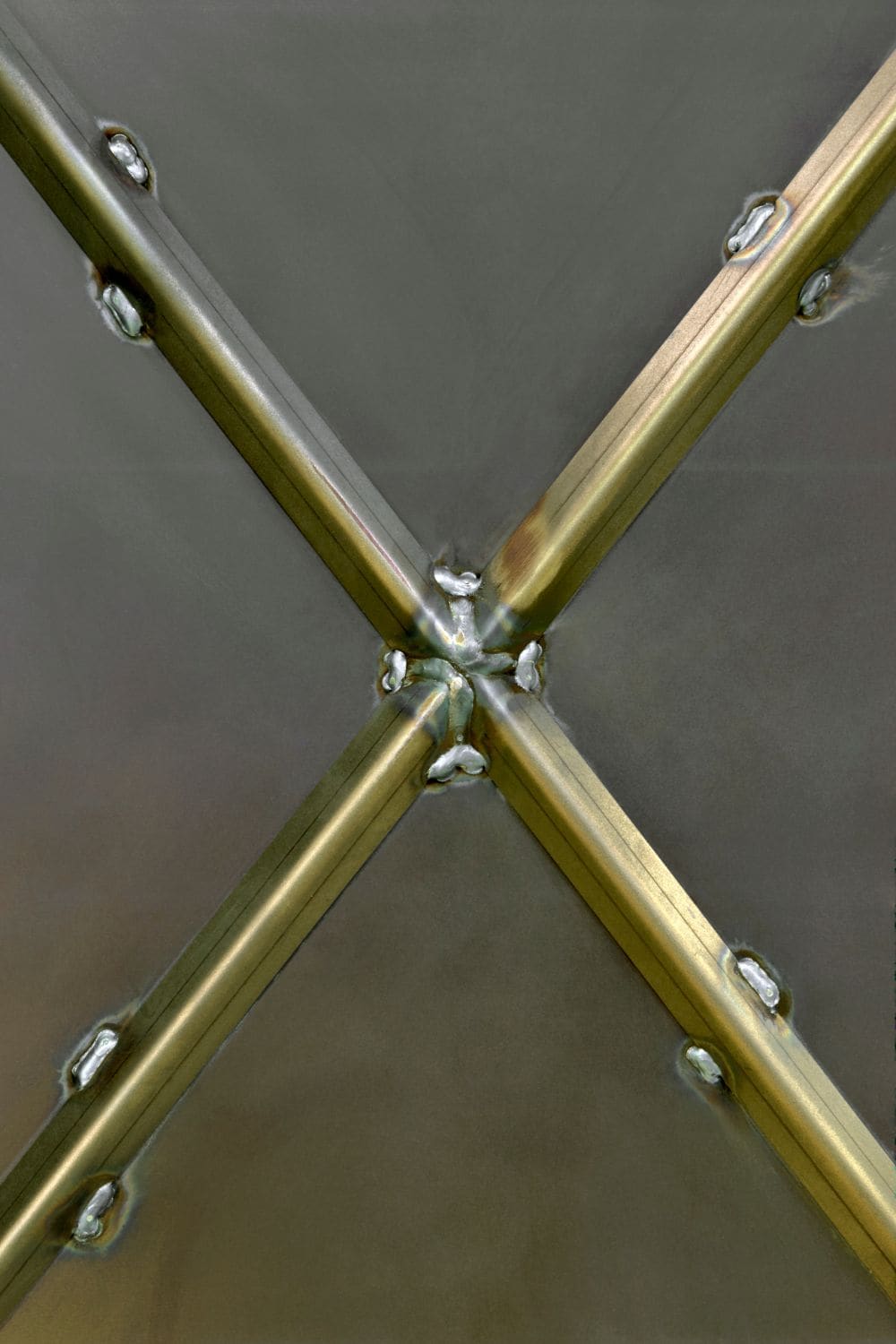

Spot Weld Bead

A spot weld bead is a small, circular weld bead used to join two pieces of metal together.

It is commonly used in the automotive industry for joining sheet metal parts.

The spot weld bead provides excellent strength and can be used to join metal parts without requiring access to both sides of the joint.

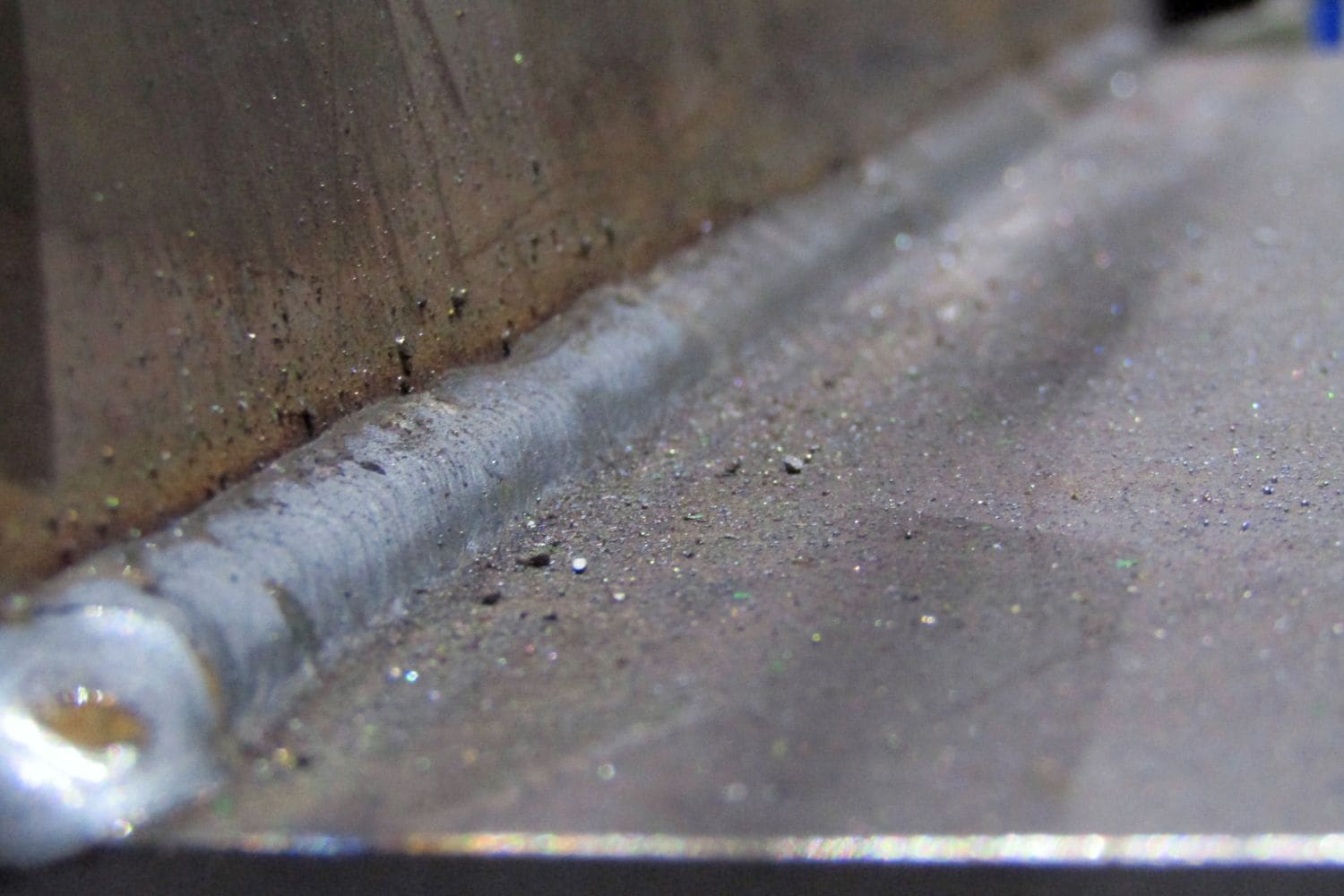

Seam Weld Bead

A seam weld bead is a continuous weld bead used to join two pieces of metal together along the length of the joint.

Unlike other beads, the seam weld one is common for manufacturing tubing, pipes, and other cylindrical components.

It is due to the fact that the bead is leak-proof and has excellent durability to be a material pipe.

When a welder joins two tubes of seam weld beads, several techniques create a good, durable, and leak-proof pipe that lasts longer than a plastic pipe.

Learn more about welding processes to know how it matches the beads in welding.

After knowing about the type of welding bead and their characteristics, let’s learn about the application of each type.

Applications of Welding Beads

There are several applications of beads in welding. The application depends on the characteristics of each bed.

Here are some lists to learn more about each bed’s application.

Beads for Construction

Welding beads are really common in the construction industry.

I think it is also the one that plays an important role in the whole industry.

They function as the fabrication of steel structures, bridges, and buildings.

In addition, fillet and butt weld beads are also the ones companies mostly use to provide good construction with good strength and load-bearing capacity.

Beads for Automotive

Welding beads are also common in the automotive industry.

The functions for fabricating car frames, engine components, and other metal parts.

Moreover, spot weld beads and plug weld beads are suitable for these applications. They provide superb strength and durability.

Hence, many companies prefer this kind of bead to ensure the quality of their products.

They also have a certain technique to ensure the welding process is smooth.

Beads for Manufacturing

Welding beads are used in the manufacturing of various components, including pipes, tubing, and sheet metal parts.

Seam weld beads are an excellent component. It is sturdy, leak-proof, and easy to weld with another metal.

That is why the pipe company loves using seam weld beds for manufacturing their pipe products.

Read Also : Understanding Welding Parameters: Your Key to Perfect Welds

Beads for Aerospace

Welding beads are used in the manufacturing of aircraft components, including fuselages, wings, and landing gear.

The strength and durability of welding beads make them suitable for these applications.

The ability to create a joint without requiring access to both sides of the joint makes plug welds and spot welds particularly useful.

Welding beads are an essential part of many welding processes.

Moreover, it provides structural integrity and joins two pieces of metal together.

The different types of beads in welding, including filet weld beads, butt weld beads, plug weld beads, spot weld beads, and seam weld beads, have different characteristics and functions.

They also have different applications in real life.