Poor welding techniques can cause various defects in the final results.

As a welding enthusiast, I have encountered many defects in my previous projects.

Then, one of the most common ones is excess reinforcement in welding.

So, what is a weld reinforcement defect?

And how to prevent it from occurring in weld joints?

Through this article, I will share my experience regarding excessive reinforcement.

What is Excess Reinforcement in Welding?

Let me define what excess reinforcement is.

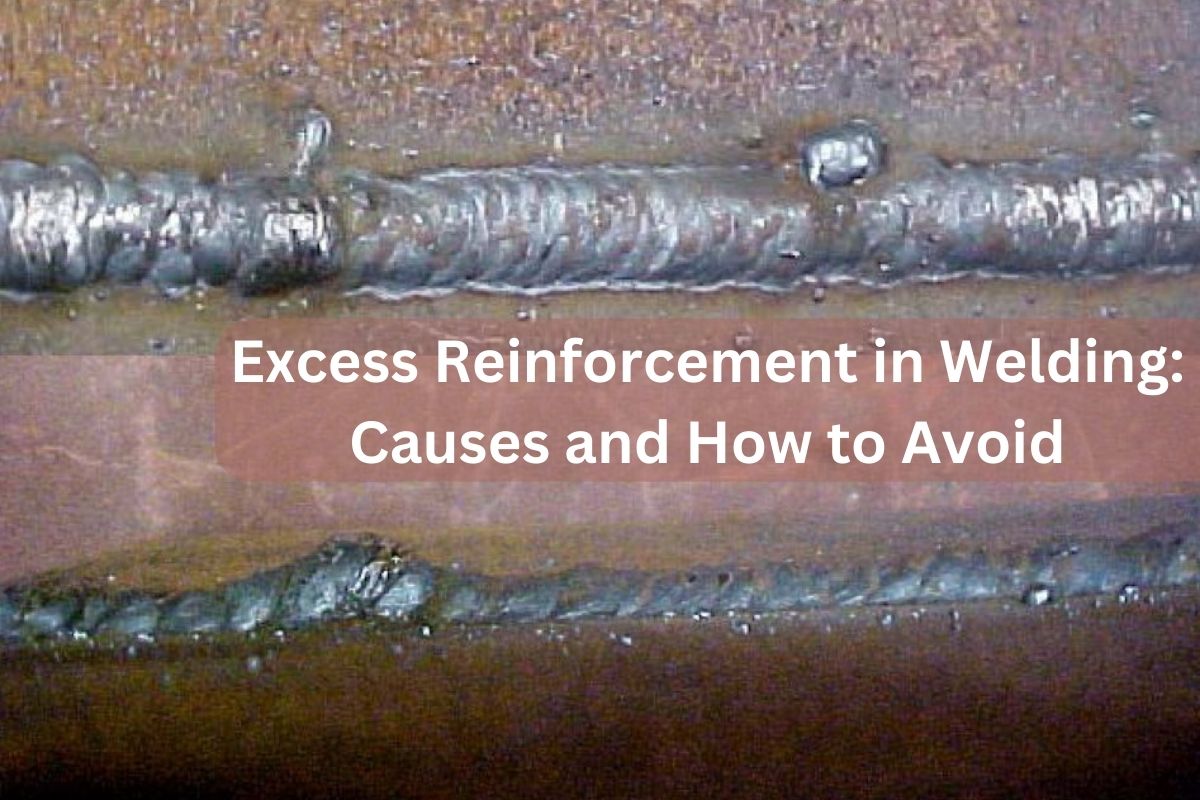

It is a kind of welding defect that occurs when the weld metal extends beyond the surface of the base metal.

In other words, the weld bead is taller or wider than it should be.

So, why is excessive weld reinforcement bad?

Of course, this defect can compromise the strength and integrity of the weld joint. Besides, the weld joint looks untidy.

This defect is easy to notice. The weld has too much convexity or build-up. So, the contour of the joint looks like a mountain.

This defect can occur when the weld joint is overfilled. As a result, the excess filler metal is accumulated above the joint.

What Causes Excessive Reinforcement Welding?

After understanding what is over reinforcement, let’s move on to the causes of this defect. Several factors contribute to overfilled joints.

The main causes of this defect are improper welding technique and parameters.

That is why the operator’s skills play an essential role in good weld joints.

These are some issues that cause overfilled joints.

- Welding parameters

Welding parameters such as voltage, amperage, and travel speed can affect the size of the weld bead.

The weld metal can build up due to excess heat if the voltage or amperage is too high. Besides, if the travel speed is too slow, it can lead to excess reinforcement.

Read Also : Understanding Welding Parameters: Your Key to Perfect Welds

- Incorrect welding technique

Welding is a skilled trade; the improper technique can lead to defects like excess reinforcement.

For example, if the welder does not maintain the correct arc length or angle, it can result in excessive weld metal build-up.

- Too Large Gap

Before welding, make sure to align the workpiece properly. This step can minimize the gap between two metal parts.

Just remember that too large gap can cause overfilled.

- Excess Flux

The shape of excess reinforcement varies.

Sometimes, its shape is ragged and uneven. The cause of this defect is excess flux on the feed wire. Besides, it is also caused by unstable travel speed.

- The Position of The Weld

Welding position can also contribute to excess reinforcement.

Gravity can pull the weld metal downwards if the weld is performed in a horizontal or overhead position. So it will accumulate and create a taller bead.

- Joint Preparation

The preparation of the joint can also play a role in causing this defect.

If you do not bevel or clean the joint properly, the weld metal will cause a wider bead.

Tips to Prevent Excess Reinforcement

Preventing the defect is better than repairing it.

So, before I start welding, I always check the entire parameters to ensure they are correct.

Here are some tips I usually do to minimize excessive reinforcement of weld.

Read Also : What is Overlap Welding: Causes and How to Avoid Them

- Use the Correct Welding Parameters

First, pay attention to the setting of the welding machine. Make sure that the amperage is correct. Do not set it too high, as it can cause excess heat.

Then, adjust the voltage. Avoid using too low voltage. Moreover, it is also essential to maintain the constant speed of the torch.

Always check welding procedure specifications for guidance.

- Use Proper Technique

Proper welding technique is essential in preventing excess reinforcement.

Maintain the correct arc length and angle to prevent any defects, including overfilled joints.

It is good to move the electrode at a higher welding speed. Faster movement can prevent excessive metal build-up.

- Prepare The Joints and Alignment

Clean and bevel the joint as necessary to ensure proper penetration. Besides, align the metal workpiece correctly to avoid a larger gap.

- Use the Correct Welding Consumables

Choose the appropriate size and type of electrode or wire according to the type of metal that you want to weld.

Always refer to the recommendation of the manufacturer for the best guidance.

Those are several tips that I usually do before and during the welding process. Implementing the tips above will be able to minimize the chance of weld build-up.

However, proper training is also essential. The more you practice, the more skillful you are.

Additionally, always prioritize safety in welding. Use personal protective equipment and conduct safe welding practices.

Read Also : What is Welding Spatter: Causes and Tips to Avoid It

How to Fix Excess Reinforcement?

In fact, reinforcement is an important part of welding.

The reason is reinforcement can increase the strength of joints. However, if the reinforcement is in excess, it is considered a defect.

Then, what is the maximum reinforcement?

The acceptable height of reinforcement for pipe is 1/16 inch. Besides, the maximum reinforcement for metal plates is only 1/8 inch.

Since it is a defect, you must repair it to improve the welding quality.

So, how to fix excess reinforcement? There are two repair tips I want to share.

First, grind excessive weld reinforcement. It is the most common method to correct the size. Just use a grinding wheel to remove excess weld metal. Be careful when grinding so it does not touch the base metal.

Then you can also repair it by using a carbon arc. Carbon arc gouging offers a more precise result than the grinding method.

I often use this tool to remove a large amount of weld. Additionally, the gouging process is faster than using a grinding wheel.

Remember, welding is a skill that takes practice and experience to master.

So, if you encounter this defect, you should not be discouraged. Just keep practicing to improve your technique.

This way, you can produce flawless welds.

In conclusion, excess reinforcement in welding can be a serious problem.

So, make sure to consider welding parameters, techniques, as well as joint preparation to minimize the risk of excess reinforcement.