If you want to pursue a welding career, you must learn different kinds of welding skills and sharpen your knowledge in welding related topics.

One of the topics you may want to cover is welding flames.

Learning this topic will help you produce a good quality weld and ensure you follow a safe working procedure.

Without further ado, let’s start from the beginning.

What are Welding Flames?

As the name suggests, welding flames refer to the flames used in welding applications.

These flames have a temperature so high they can melt metal.

Your knowledge about welding flames can help you weld better. Besides, it can also protect you from preventable injuries.

Welding flames come from fuel combustion. When the gas burns and produces a flame, you can use the flame to weld according to your desire.

But before that, you need to know the different types of welding flames.

Types of Welding Flames

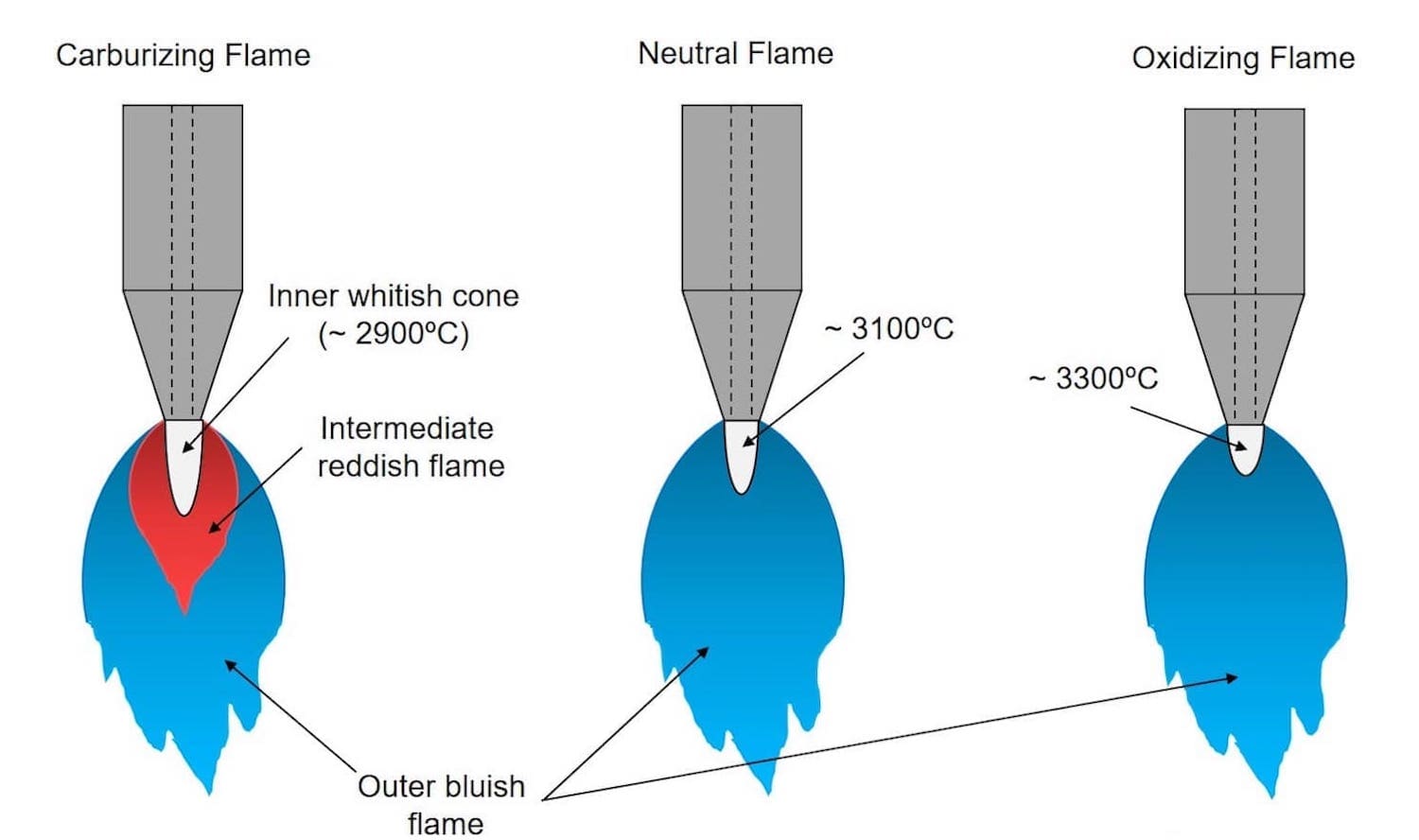

There are three types of welding flames commonly used in the industry. They include neutral flame, oxidizing flame, and carburizing flame.

1. Neutral Flame

In short, it’s a normal flame. It does not cause any chemical reaction during the welding process.

This welding flame has a balanced gas and oxygen ratio. It is the ideal flame for welding because it produces a clean, efficient burn.

Neutral flame works with various types of metals, such as copper, aluminum, cast iron, and many more.

The flame has a light blue color, with a white cone on the inside of the flame.

The temperature of the inner flame can reach up to 6.000ºF (3.300ºC).

Read Also : Welding Porosity: What It is, Causes and How To Avoid

2. Carburizing Flame

While a neutral flame has a perfect amount of acetylene, the carburizing flame has a little too much of it.

This flame causes a chemical change in the metal by producing iron carbide.

The white feather that wraps the inner flame cone shows you that the acetylene content is too excessive.

If this “acetylene feather” grows twice longer than the inner cone, it is called 2x flame.

The temperature of the carburizing flame can reach up to 5700ºF (3149ºC) at the tip of the inner core.

You can create this flame by starting with a neutral flame. Then you slowly open the acetylene valve until you see the white feather forming.

A carburizing flame has three flame areas. The inner part is white in color. The white “feather” part surrounds the inner part. And the last one is the outer flame, which is light blue.

When you apply a strong carburizing flame on steel, the flame boils the steel while the steel absorbs carbon from the flame. The end result is a brittle weld.

You can use this flame type for the following metals: lead, carbon steel, aluminum alloys, and oxygen-free copper.

3. Oxidizing Flame

You will get an oxidizing flame when the oxygen content is higher than acetylene.

The reaction between oxygen and metal during the welding process causes the flame to have a higher heat level.

The temperature of this flame can reach up to 6300ºF (3482ºC). Oxidizing flame has a light purple inner cone. The cone is smaller than the one in a neutral flame.

You can use an oxidizing flame for welding metals that do not easily oxidize, such as manganese steel, copper, and cast iron.

Using metals that are prone to oxidation will ruin the weld.

The high oxygen level will react with the metal, negatively impacting the bond.

When the right materials are used, the oxidizing flame can give you a high quality weld.

The Best Welding Flame

The best welding flame, I think, is the one that suits your needs. Even neutral flame, which has been considered the most versatile, has its own limit.

Sometimes you will have to increase your flame temperature. Other times, you will need to adjust the setting to work on a different metal piece. There is no “no one fits all” scenario.

But welding flames are just one among many things that affect weld quality A welder’s skills, for instance, determine the success of a project. So does the welding equipment.

Gas Welding Tips

You can’t talk about welding flames without discussing the gas welding itself.

This welding process is different from the one done with welding machines.

Gas welding uses fuel and combustion to create metal-melting flames, while more modern welding techniques use electrical currents to weld the metal.

Here are some gas welding tips for you:

1. Choose The Right Gas

You can use acetylene for welding thicker metals because it gives you a hotter flame. This is what most professional welders use.

However, you can pick propane if you want to look for something more economical.

2. Use The Correct Nozzle

Based on the thickness of your material, pick the right nozzle size. Use bigger nozzles for thicker metals and smaller ones for thinner metals.

3. Use The Standard Flame

If you need to use the other two welding flames, pick a neutral flame as your standard.

The result is quite predictable, so you don’t have to worry much about the end result.

4. Clean Your Materials

Clean materials will make the welding process easy. So clean your materials before you weld them and clean thoroughly.

You can use sandpaper or chemicals to clean them, making sure no oil or dirt is left.

5. Use a Welding Rod

Your choice of welding rod should be based on the metal you use. Various kinds of welding rods are available in the market.

Some of them include aluminum, steel, and copper.

6. Hold The Torch at a Correct Angle

You should hold the torch at a 45-degree angle to your work material.

This angle allows an even distribution of heat, so your flame can fuse the joint perfectly.

Read Also : Inverter vs Transformer Welder: Understanding the Advantage

7. Practice Good Techniques

You can only master welding skills with a lot of training.

Perfecting your techniques takes time and effort. For this reason, you should make a logical approach to your training.

To save money, use scrap metal instead of a new metal piece. This way, you can train yourself effectively because you won’t be too afraid to make a mistake.

Start your training with simple welding techniques before moving on to a more complicated one. This will encourage you to keep training.

You learn a few things about the gas welding process by learning about welding flames. If you continue reading more articles about welding, your skills will improve in no time.