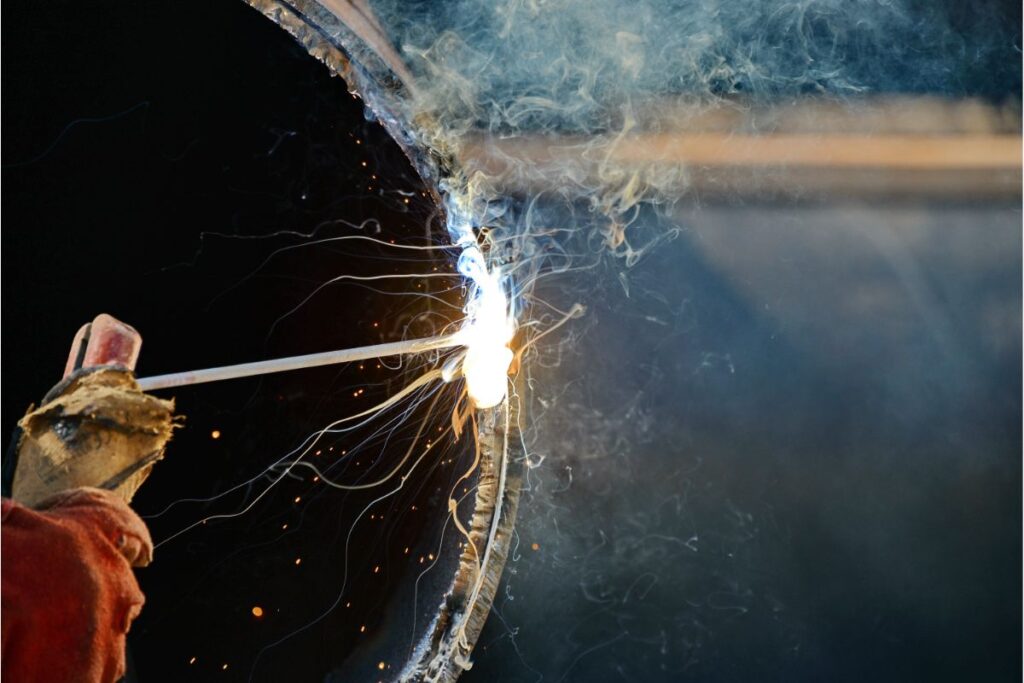

Welding pipes is certainly different from the usual metal welding. It’s commonly performed at high-risk locations and conditions.

Stick welding pipe may have their own challenges.

However, it still becomes the top option for welding pipes.

What are the differences between using stick welding techniques on pipes and other steel materials?

What makes it the most popular choice for welding pipes?

Let’s find out more about it.

Understanding Stick Welding Pipe

The main reason stick welding becoming the first option for pipe welding is its simplicity.

It’s the easiest welding technique compared to the others. Even beginners will not have any problem mastering this technique.

Stick welding is not only easy, but it also requires fewer pipe welding tools.

Welding pipe does not require special equipment. It’s relatively the same as in welding other materials.

Usually stick welding is done on a flat surface.

However, it requires adjustment to work on the curved surface of a pipe.

This is probably the most difficult part of welding a pipe. You need to work on the vertical up position, which could use some practice.

Read Also : Is Stick Welding Hard? Likely Challenges Exposed

Different Preparations for Stick Welding Pipe

Before moving on to welding the pipes, there are some things that you need to prepare first.

The first step is to check on the metal thickness of the pipe.

Different thickness requires different preparation. If you are working on a thin metal pipe, then it doesn’t need special preparation.

However, it’s different if you’re working on a thick metal pipe. It will require you to bevel on the edges.

This small trick helps the weld to run to this space and not spill over or run down to the side.

Not only that, but this will also give better penetration to the pipe and a much stronger weld on the pipe.

The next trick is to leave something commonly known as a root gap which is a small gap between the piece.

Keep this gap small enough since it will only be used to contain the first weld.

The first weld will then pass this gap and penetrate the pipe’s backside.

Another important preparation is to clean the equipment.

It’s important to clean the grinder, saw, and plasma cutter.

Each piece of equipment must be clean of excess metals from previous works. It also must be clean of rust, dirt, fluid, or oil.

The result on the inside and outside of the pipe will not be as smooth as expected if there’s any leftover dirt on the equipment.

Purging the pipe is necessary for certain reasons. This step ensures the inside area of the pipe is free from contaminants, including oxygen.

Moreover, if the pipe is used for food or related to high pressure pipe welding procedure, purging will ensure its sanitary requirements.

Techniques for Welding Pipe

When welding pipes, the main technique is to use vertical up angle only.

Start to work from the bottom part of the pipe and move upwards. Put the torch at 90 degree angle and maintain this angle until reaching the top of the pipe.

The main trouble here is this angle will put your body in a weird position for a long duration.

Moreover working vertically up on stick welding is difficult to control.

Since stick welding does not require welding pipe fittings, it’s important to ensure the setting is correct to prevent burning through the pipe.

Read Also : Is Stick Welding Electrode Positive Or Negative? Detailed

Work slowly on weld manipulation since you just need to trap slag into the weld.

Without a doubt, the stick welding pipe method is still the most popular choice for welding pipes.

However, welding pipe is not as easy as it seems.

In order to do a proper pipe welding, you will need detailed preparation, correct techniques, training, and fully functioning equipment.